Creating a Drone from Scratch

Last year I decided I wanted to learn about electrical systems and make something from scratch. I have a drone license so I wanted to make a drone myself, big mistake, $400, countless hours, tons of banging on my desk and I still havn't finished it as I've had lots of set backs. However, I'm learning a lot and am committed to finishing this stupid drone. This is where I'm at and what I've learned so far.

Step 1: Denial

I started by being hopeful, "yea I can make a drone" I thought. What I didn't realize was how much it would cost, which is why Mr. Crabs is here, and how much soldering I had to do. News flash I suck at soldering. Youtube was awesome and I found a good video that helped me find the stuff I needed for around $200. A frame for the drone, the drone controller, the motors, a soldering iron, the FPV transmitter, the camera, the batter, and a few other miscilaneous things I wanted.

Step 2: Pain

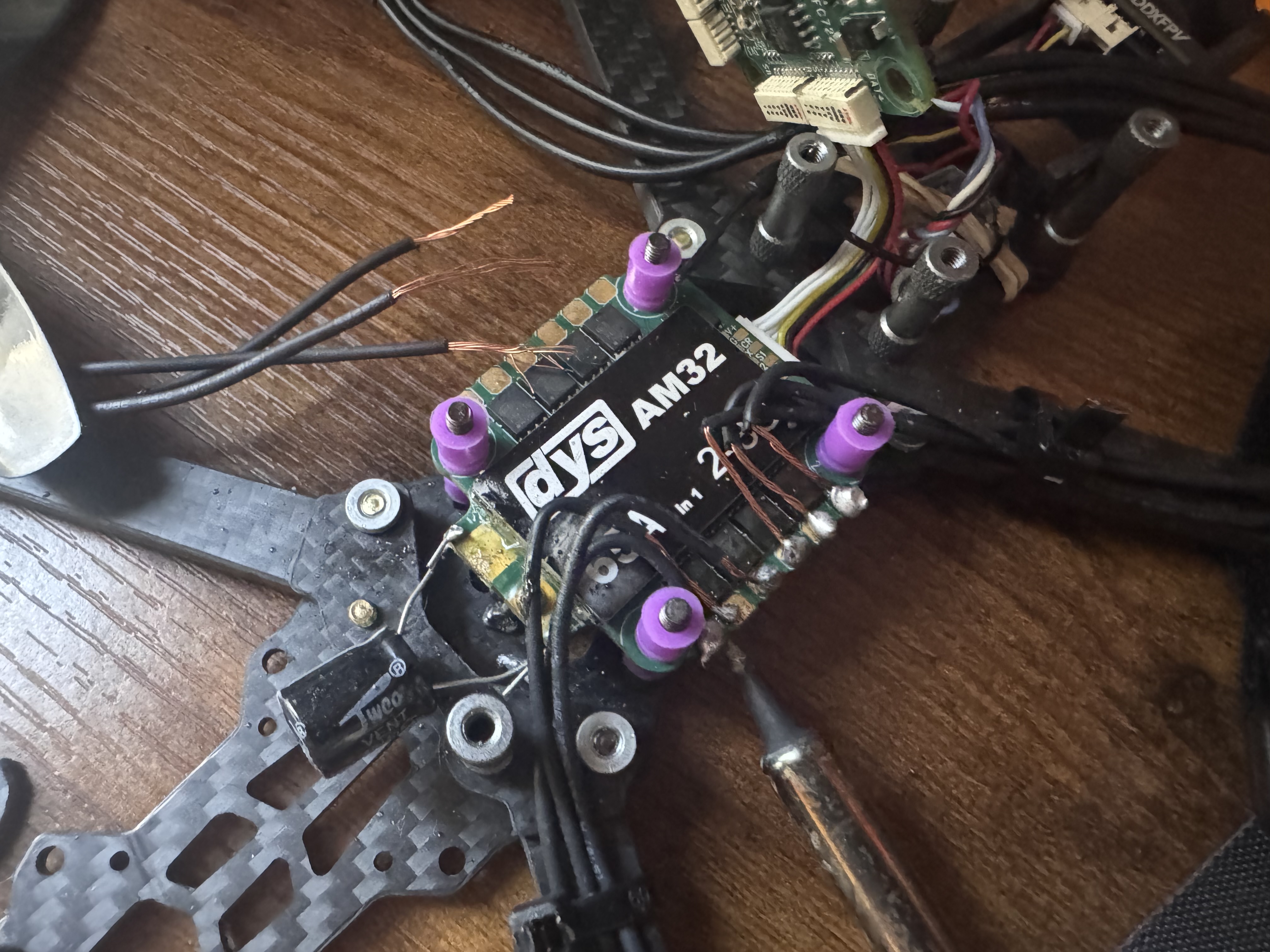

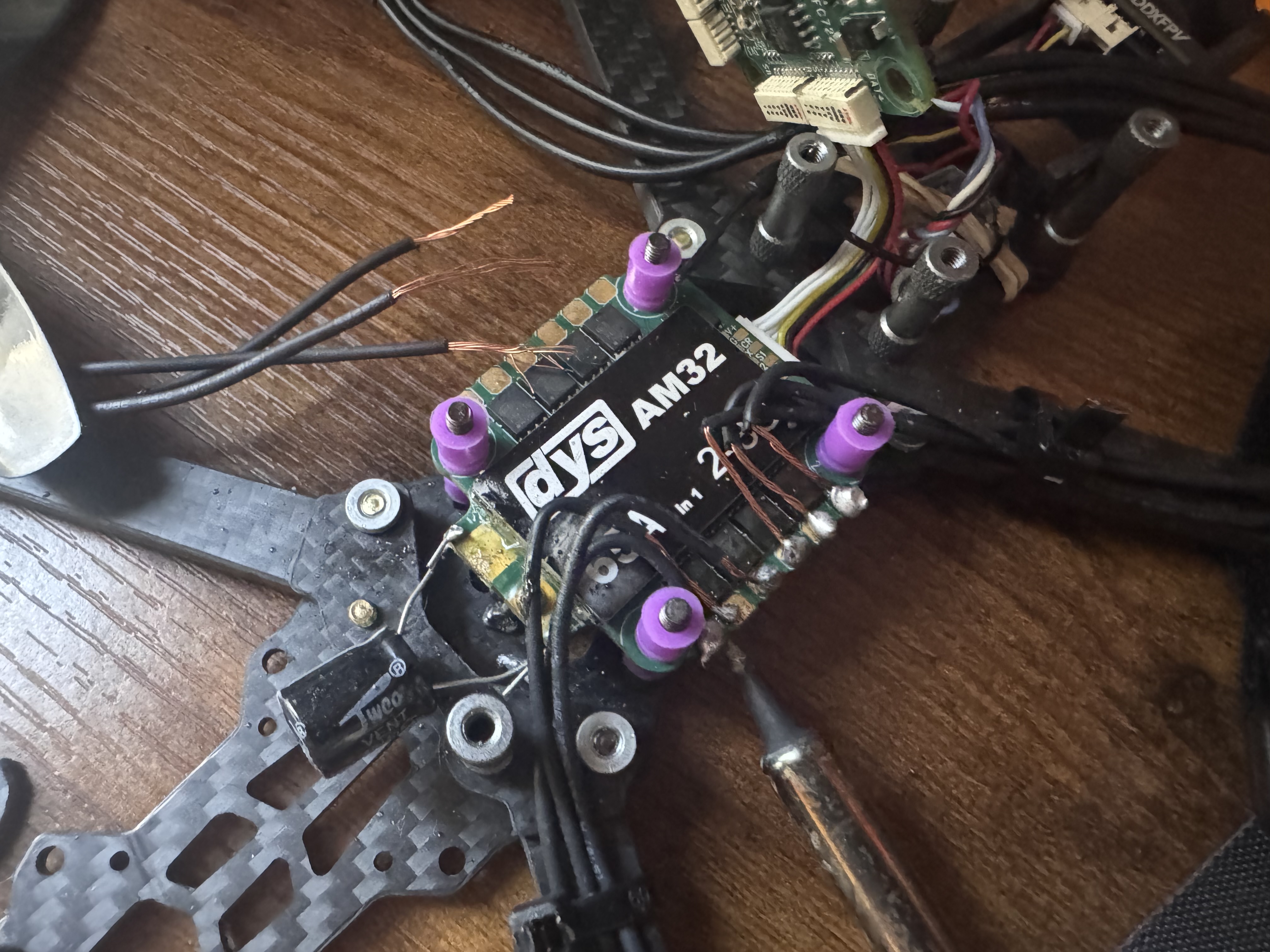

When I purchased all of these items I was on an internship and didn't have time to assemble them, the summer however, that was when I decided to get to work. I quickly realized I only had half of the drone controller, so I spent another 50 bucks. Sick. Then I actually had to assemble the drone, this was super fun but this is also when I realized I sucked at soldering. The wire would stick, and then move, eventually I was able to get it to work and I assembled the entire frame and was able to configure the Drone on ESC Configurator and BetaFlight'

Step 3: Actually Doing fun Stuff with ESC Configurator

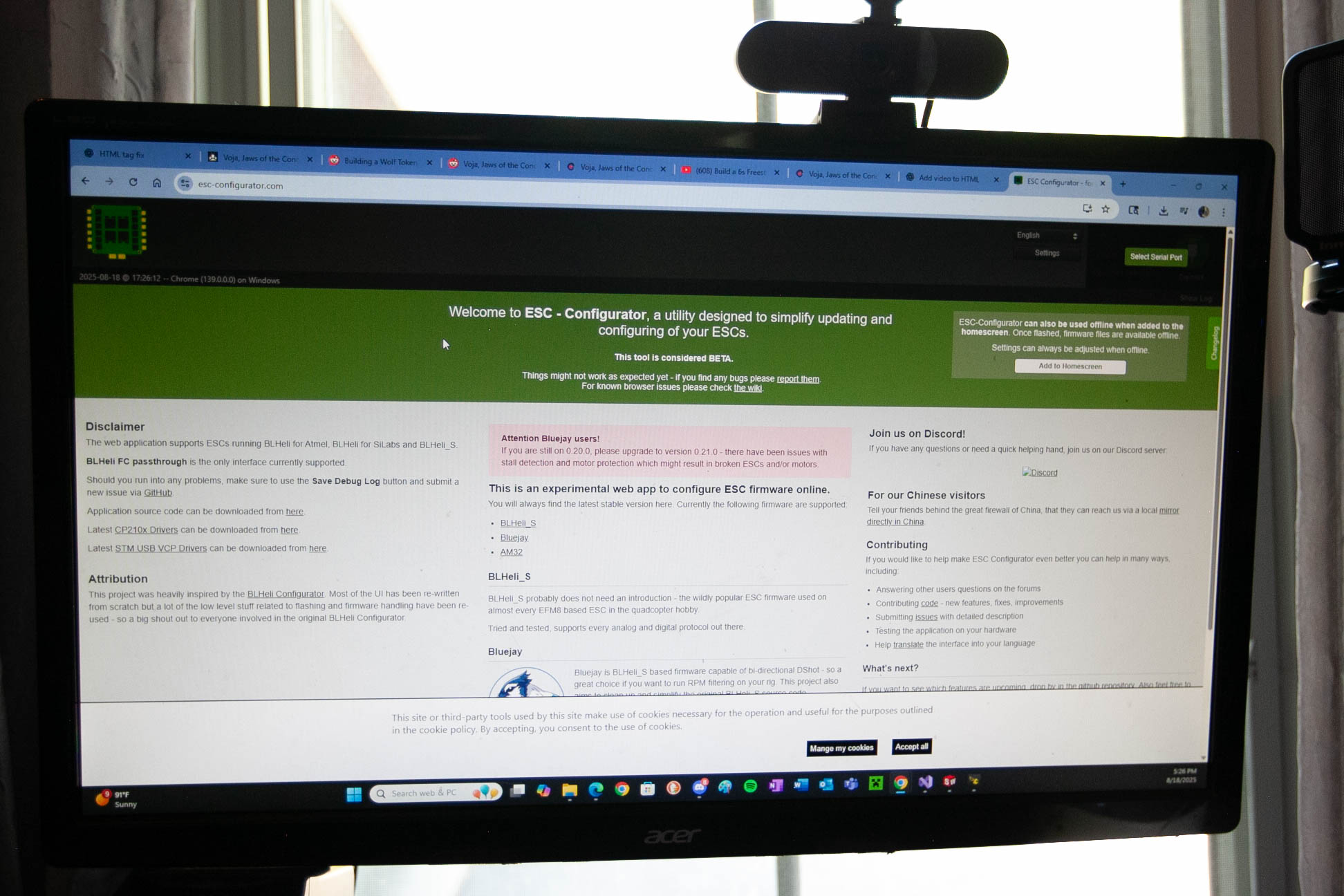

ESC Configurator is a pretty short step. You connect your drone to your computer and you are tuning some settings and then uploading them to the flight controller.

Step 4: More fun still but BetaFlight

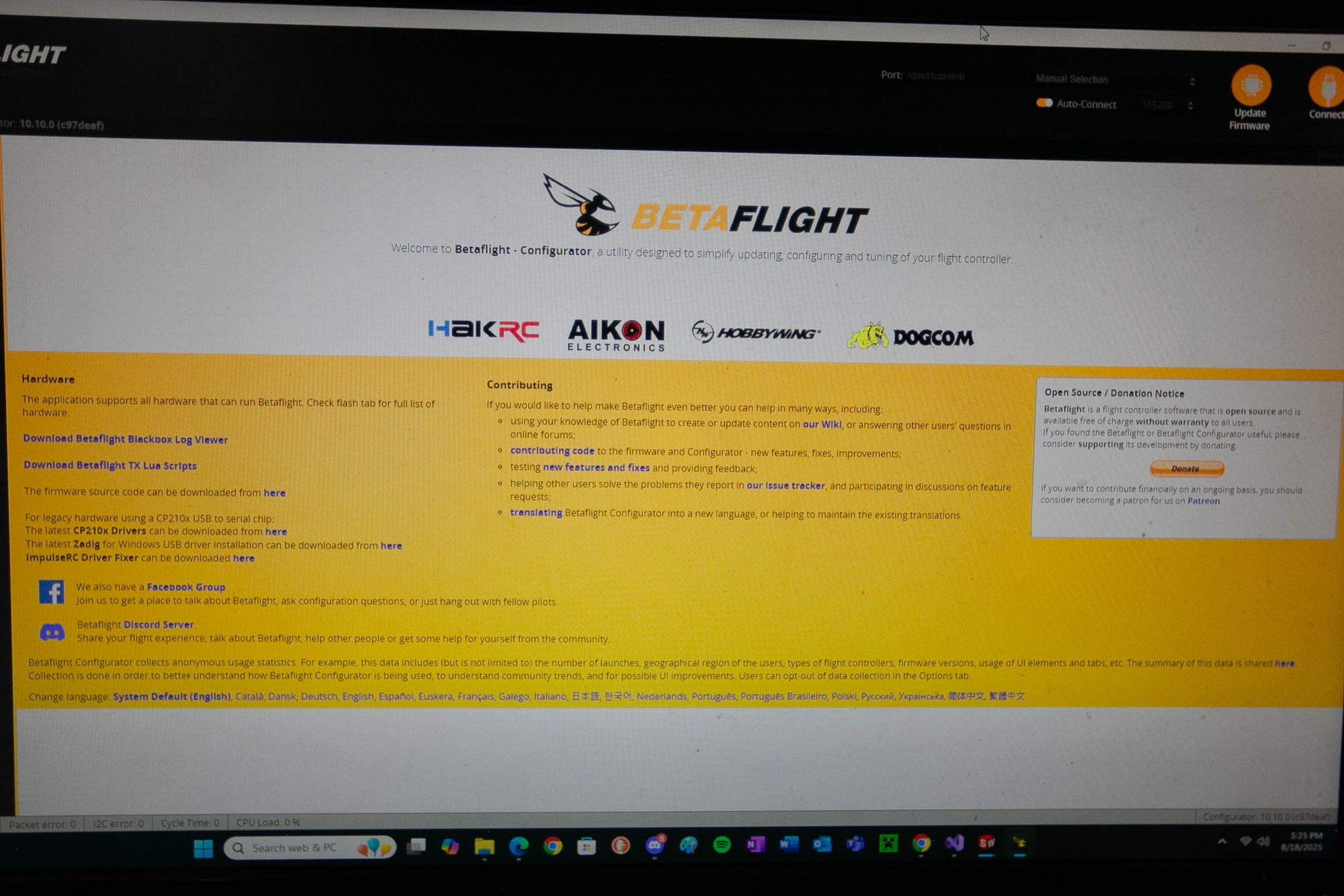

BetaFlight is where you actually import all of your settings, connect your physical Drone Controller, and set up all settings for the phone. This is the final step before your drone is ready to go, and where everything fell apart for me.

Step 5: Despair

As I was messing around with Betaflight I noticed my motors were all beeping except for one, I checked it and realized that it wasn't properly soldered onto the controller. I tried to resolder it and burned through the plate, forcing myself to buy another one. In addiiton connecting the main battery to the plate is extremely diffcult and I am bad at soldering. I was so close to having the drone done yet it all fell apart. I'm not giving up and am gonna finish it but it's big sad.'

This project, while still on going, was and is great. It forced me to tackle challenges I've been exposed to, but still forced me to think of new things. It also challenged me with soldering as I've never soldered before. Learning how the electronics work, how connectivity works with soldering, and in general how precise you must be was great. In addition to figure out the configuration of the drone.

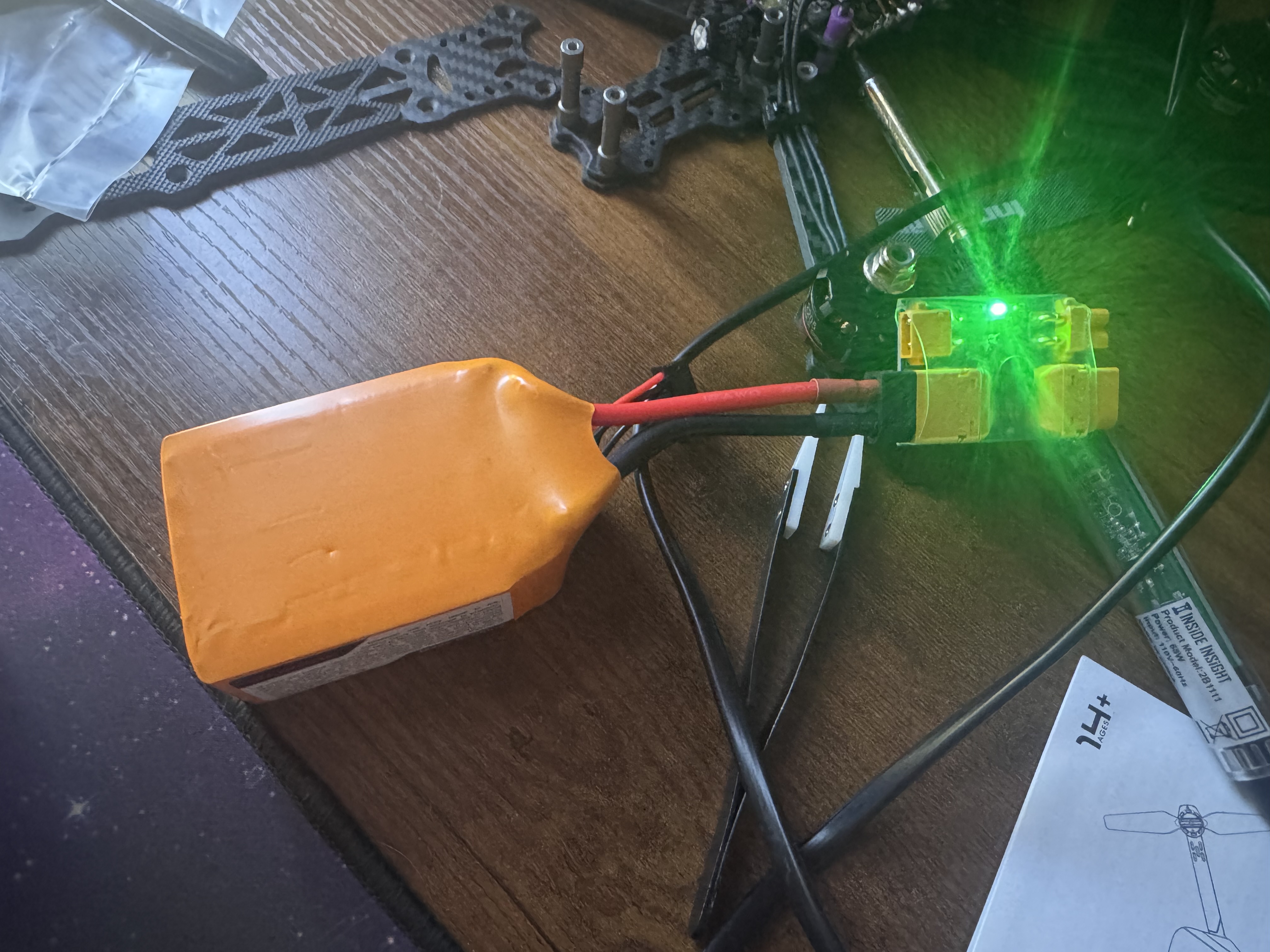

This was something else I learned with the drone while making it. If their's a short circuit it can fry the entire drone. So I used a smoke stopper. This tests for short ciruits and warns me, the green light means we are good to go. In the picture it's not connected to anything but I just wanted to share what I learned from that.